Kilgore : Napalm, son. Nothing else in the world smells like that. I love the smell of napalm in the morning.

– Apocalypse now

Cannabis, Son. Nothing else in the world smells like that. I love the smell of Cannabis in the morning. But does everyone else?

-Adapted Apocalypse now quote.

Sometimes a good nose will get you $100 more per pound. We all love the bag appeal of gaseous flower reeking when we buy it, but what about the 8 weeks it was in flower, the time spent in cure? How about the massive veg and mother canopy? All stages fill the air with unmistakable aromas.

These aromas can get you noticed in the market and noticed in the community…in a bad way. Most municipalities require odor mitigation plans (good neighbor laws) but methods to deal with these smells vary.

Room design and pressurization, airflow, purges, filters, chemicals, ROS, Ozone, UV, SOPs…there is a lot to consider when you are mitigating odors. And this doesn’t even account for the guy down the street with a Nasal Ranger (see image below).

Let’s start with the what, the why, and then get into solutions…so what is that smell?

VOCs explained:

Plant Metabolism: Cannabis plants naturally produce certain VOCs as part of their metabolic processes. These compounds, such as terpenes, contribute to the plant’s aroma and flavor.

Environmental Impact: In an indoor cultivation setting, the use of certain products, such as fertilizers, pesticides, and other chemicals, can release VOCs into the air. These emissions can have environmental consequences, and their regulation may be subject to local or regional guidelines.

Solvent extraction: This creates VOCs that necessitate explosion-proof fans, safety air exchanges, and air quality monitoring. This is one obvious place where you find VOCs in a facility if they do this type of extraction.

Air Quality and Odor Control: The release of strong odors from cannabis cultivation facilities can be a concern for neighbors, employees, and regulatory authorities.

Compliance and Regulations: Due to potential environmental and public health concerns, many regions have regulations governing the emission of VOCs from cannabis cultivation facilities. Cultivators may need to implement measures to monitor and control VOC levels to comply with local laws.

Technology and Best Practices: Cultivators may employ various technologies and best practices to manage VOCs. This can include the use of air purification systems, carbon filters, and other methods to control odors and reduce the environmental impact of volatile compounds.

Terpene Preservation: While controlling undesirable VOCs is important I see every scent as a “$” and a reduction in customer experience. Preserve and protect what you can without disturbing the community around you.

BVOCS:

BVOCs stand for Biogenic Volatile Organic Compounds. Unlike traditional VOCs, which are often associated with industrial processes and human activities, BVOCs are organic compounds emitted by living organisms, including plants such as cannabis. In the context of cannabis cultivation, BVOCs play a crucial role in the plant’s natural processes and can influence both the plant itself and its surrounding environment. Here are some key points regarding BVOCs in cannabis cultivation:

Terpenes: Terpenes, which are a type of BVOC, contribute significantly to the characteristic aroma and flavor of cannabis. They are produced in the trichomes of the plant and are responsible for the diverse scents found in different cannabis strains. Terpenes also have potential therapeutic effects and can contribute to the overall experience of consuming cannabis.

Plant Defense Mechanism: BVOCs, including terpenes, can serve as part of the plant’s defense mechanism against pests and pathogens. Some terpenes have antimicrobial and insect-repelling properties, helping the plant fend off potential threats.

Environmental Signaling: BVOCs can act as signaling molecules within the plant and between plants. They play a role in communication between different parts of the plant, as well as in interactions between plants. For example, certain BVOCs released by a stressed plant can signal nearby plants to activate their defense mechanisms.

Ecological Impact: BVOCs contribute to the overall ecological interactions in the environment. They can influence atmospheric chemistry, participate in the formation of aerosols, and even affect local weather patterns. The complex interactions involving BVOCs are part of the broader field of study in plant ecology.

Cultivation Practices: Cannabis cultivators may focus on optimizing the production of specific terpenes through various cultivation practices, such as selecting specific strains, adjusting environmental conditions, and using nutrient strategies. The goal is to enhance the desired aromatic and therapeutic qualities of the cannabis plants.

VOCS, BVOCS, and the need to control them:

- Human Health Concerns.

- Impact on Atmospheric Chemistry Models.

- Odor Control for Compliance and Abatement Plants.

- What are Those BVOCs Worth- Should we be Capturing them?

- How do we Properly Regulate and Enforce them?

Options for Controlling Odors:

Advanced Ventilation Systems:

- Invest in high-quality ventilation systems with HEPA/Merv13 filters to control and filter air within the cultivation facility.

- Use exhaust fans strategically to ensure proper pressures, air exchange and minimize the buildup of VOCs.

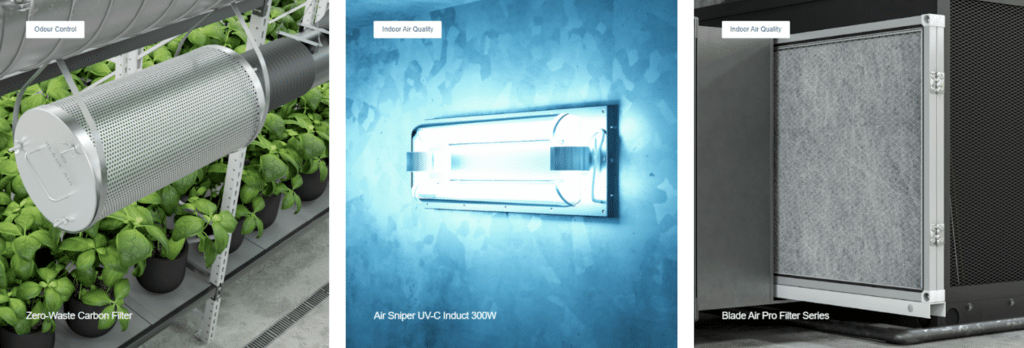

Carbon Filtration:

- Install activated carbon filters in ventilation systems to adsorb and neutralize odorous compounds, including BVOCs.

- Regularly maintain and replace carbon filters to ensure optimal performance.

Enclosed Cultivation Spaces:

- Consider enclosed cultivation spaces to better control air quality.

- Implement positive pressure systems to prevent air leakage and odors from escaping into neighboring areas.

Odor Neutralizers:

- Utilize odor-neutralizing agents or technologies designed to neutralize and eliminate unwanted odors.

- Test and choose products that are safe for both the environment and the cannabis plants.

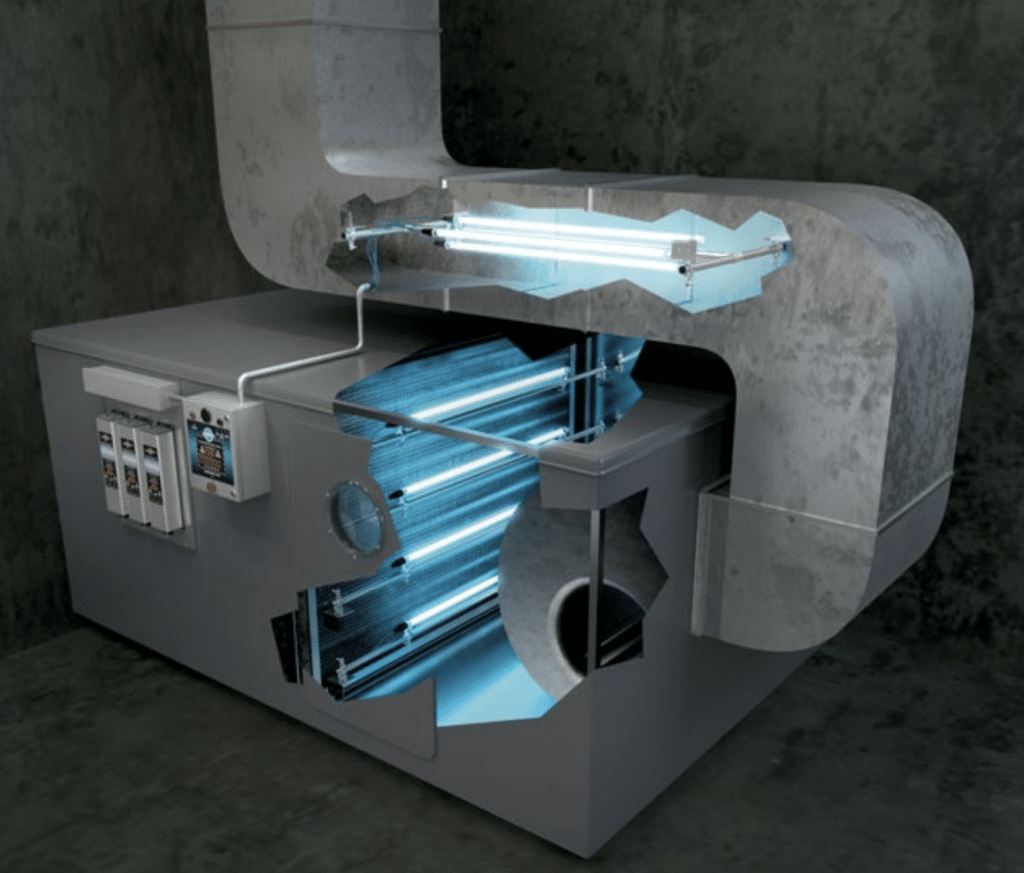

HVAC Systems with Air Scrubbers:

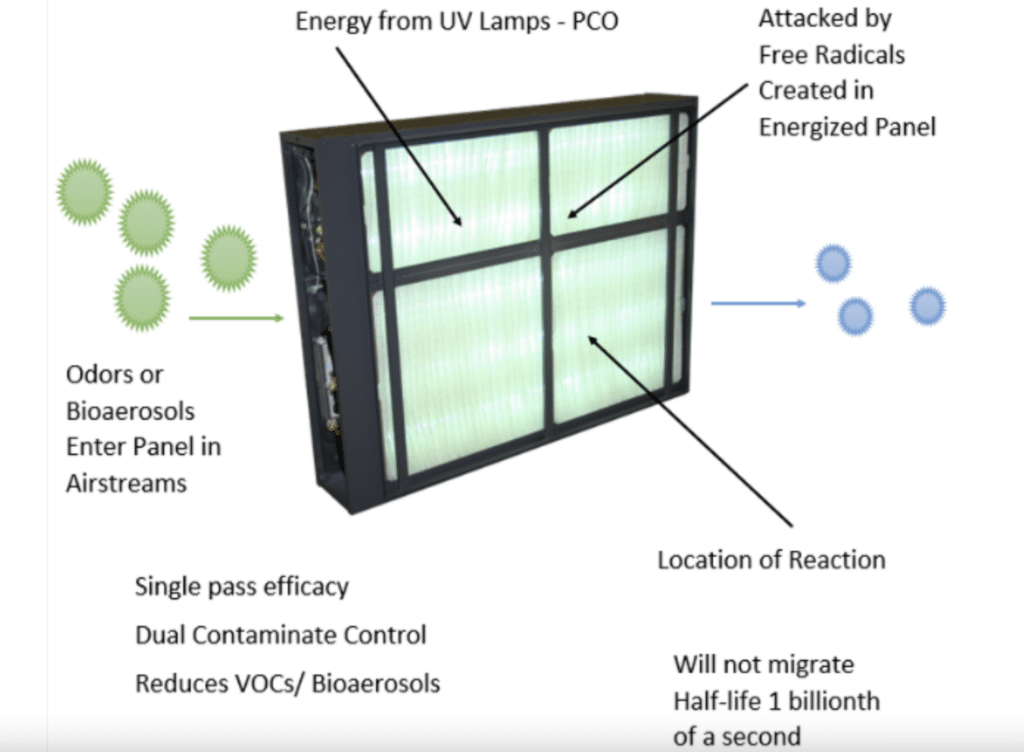

- Install HVAC (Heating, Ventilation, and Air Conditioning) systems with air scrubbers, UVC, PCO or other tech to remove contaminants and odors from the air.

- Regularly service and maintain HVAC systems to ensure efficient operation.

Airtight Facility Design:

- Design cultivation facilities with airtight construction to minimize the escape of air and odors.

- Implement well-sealed doors, windows, and entry points.

Strategic Use of Exhaust Systems:

- Direct exhaust systems away from populated areas, ensuring that odors are dispersed effectively.

- Consider using odor control technologies in exhaust ducts.

Compliant Cultivation Practices:

- Follow local regulations and guidelines related to odor control and emissions.

- Keep up-to-date with changing regulations and adjust cultivation practices accordingly.

Community Engagement:

- Establish open communication with the local community to address concerns and demonstrate commitment to responsible cultivation practices.

- Consider implementing community-friendly initiatives, such as tours or informational sessions, to foster positive relationships.

Stages of filtration:

From outside to inside to back out… what’s the cycle and where can you impact? At what cost and with what level of effectiveness? Here are some guidelines:

- Assessment and Planning:

- Evaluate the specific VOCs and BVOCs emitted in the cannabis facility.

- Identify the sources and quantities of emissions.

- Determine the applicable regulations and standards.

- Develop a filtration strategy based on the assessment.

- Selection of Filtration Technologies:

- Choose appropriate filtration technologies tailored to the identified VOCs and BVOCs.

- Consider options such as activated carbon filters, biofilters, and other advanced filtration systems.

- Assess the compatibility of selected technologies with the scale and nature of the cannabis operation.

- Implementation and Installation:

- Install the chosen filtration systems in key areas of the facility where emissions occur.

- Ensure proper integration with existing ventilation and air handling systems.

- Conduct training for personnel on the operation and maintenance of the filtration equipment.

- Monitoring and Optimization:

- Implement continuous monitoring of VOC and BVOC levels to assess the effectiveness of filtration.

- Optimize filtration parameters based on real-time data and feedback.

- Regularly inspect and maintain filtration systems to maximize efficiency.

- Budget Considerations:

- Allocate funds for the initial assessment, including emissions testing and regulatory compliance analysis.

- Budget for the purchase, installation, and maintenance of filtration equipment.

- Consider long-term operational costs, including energy consumption and replacement of filter media.

Measurement of Success: Success in cannabis VOC and BVOC filtration can be measured through several key indicators:

- Emission Reduction: Measure the percentage of VOC and BVOC emissions effectively captured and reduced by the filtration system.

- Compliance: Ensure adherence to regulatory emission limits and standards.

- Air Quality Improvement: Monitor improvements in air quality within and around the facility.

- Product Quality: Assess the preservation of cannabis product quality, including aroma and flavor profiles.

- Operational Efficiency: Evaluate the efficiency and reliability of the filtration system in real-world conditions.

- Cost-effectiveness: Measure the overall cost-effectiveness of the filtration strategy, considering both initial investment and ongoing operational expenses.

Conclusion:

The need to control VOCs and BVOCs stems from concerns related to human health, atmospheric chemistry, compliance with regulations, industry reputation, and the preservation of product characteristics. The adoption of various technologies and best practices, such as advanced ventilation systems, carbon filtration, and compliant cultivation practices, offers cultivators a comprehensive toolkit to manage and mitigate the impact of these volatile compounds.

Additionally, understanding the distinct role of BVOCs in plant metabolism, defense mechanisms, environmental signaling, and ecological interactions emphasizes their importance in the broader context of cannabis cultivation. Terpene preservation becomes not only a regulatory requirement but also a means to enhance the economic value of the product and customer experience.

We have come a long way as cultivators, and regulators but ultimately, successful filtration strategies require a holistic approach that integrates technological solutions, compliance with regulations, community engagement, and continuous monitoring. By navigating through the stages of filtration and measuring success against key indicators, cannabis cultivators can strike a balance between industry growth and responsible, sustainable practices, ensuring a positive impact on both their business and the surrounding community.

Additional recourse:

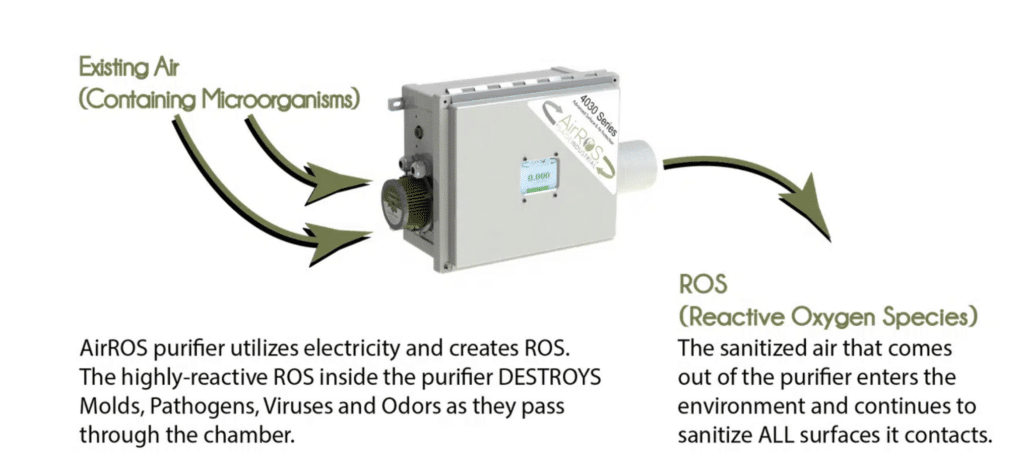

Phase 1- Primary Air Cleaning

Placed within your room’s airflow, air from the environment containing microorganisms enters the purifier’s internal chamber. The reaction chamber creates non-thermal plasma and generates ROS. ROS is comprised of 5 short-lived, highly Reactive Oxygen Species:

- Atomic oxygen,

- Singlet oxygen,

- Hydroxyl radical,

- Superoxide and

- Peroxynitrite

These break down carbon-to-carbon bonds that sanitize the air and destroy all bacteria, molds, viruses, and other pathogens as they pass through the reaction chamber.

Phase 2- Secondary Surface & Air Cleaning

Provides Surface sanitation and continued Air sanitation. The purified air now diffused into the environment contains longer Reactive Oxygen Species:

- Gas-phased H2O2- hydrogen peroxide

- Low concentration levels of O3-ozone

That further sanitizes room air and surfaces. So again, in addition to treating the ambient air as it passes through the reaction chamber, using the H2O2 and O3 diffused into the environment, our units will further sanitize all Surfaces and control Odor, resulting in clean air and surfaces 24/7.

UVC:

Kilgore : Napalm, son. Nothing else in the world smells like that. I love the smell of napalm in the morning.

– Apocalypse now

Cannabis, Son. Nothing else in the world smells like that. I love the smell of Cannabis in the morning. But does everyone else?

-Adapted Apocalypse now quote.

Sometimes a good nose will get you $100 more per pound. We all love the bag appeal of gaseous flower reeking when we buy it, but what about the 8 weeks it was in flower, the time spent in cure? How about the massive veg and mother canopy? All stages fill the air with unmistakable aromas.

These aromas can get you noticed in the market and noticed in the community…in a bad way. Most municipalities require odor mitigation plans (good neighbor laws) but methods to deal with these smells vary.

Room design and pressurization, airflow, purges, filters, chemicals, ROS, Ozone, UV, SOPs…there is a lot to consider when you are mitigating odors. And this doesn’t even account for the guy down the street with a Nasal Ranger (see image below).

Let’s start with the what, the why, and then get into solutions…so what is that smell?

VOCs explained:

Plant Metabolism: Cannabis plants naturally produce certain VOCs as part of their metabolic processes. These compounds, such as terpenes, contribute to the plant’s aroma and flavor.

Environmental Impact: In an indoor cultivation setting, the use of certain products, such as fertilizers, pesticides, and other chemicals, can release VOCs into the air. These emissions can have environmental consequences, and their regulation may be subject to local or regional guidelines.

Solvent extraction: This creates VOCs that necessitate explosion-proof fans, safety air exchanges, and air quality monitoring. This is one obvious place where you find VOCs in a facility if they do this type of extraction.

Air Quality and Odor Control: The release of strong odors from cannabis cultivation facilities can be a concern for neighbors, employees, and regulatory authorities.

Compliance and Regulations: Due to potential environmental and public health concerns, many regions have regulations governing the emission of VOCs from cannabis cultivation facilities. Cultivators may need to implement measures to monitor and control VOC levels to comply with local laws.

Technology and Best Practices: Cultivators may employ various technologies and best practices to manage VOCs. This can include the use of air purification systems, carbon filters, and other methods to control odors and reduce the environmental impact of volatile compounds.

Terpene Preservation: While controlling undesirable VOCs is important I see every scent as a “$” and a reduction in customer experience. Preserve and protect what you can without disturbing the community around you.

BVOCS:

BVOCs stand for Biogenic Volatile Organic Compounds. Unlike traditional VOCs, which are often associated with industrial processes and human activities, BVOCs are organic compounds emitted by living organisms, including plants such as cannabis. In the context of cannabis cultivation, BVOCs play a crucial role in the plant’s natural processes and can influence both the plant itself and its surrounding environment. Here are some key points regarding BVOCs in cannabis cultivation:

Terpenes: Terpenes, which are a type of BVOC, contribute significantly to the characteristic aroma and flavor of cannabis. They are produced in the trichomes of the plant and are responsible for the diverse scents found in different cannabis strains. Terpenes also have potential therapeutic effects and can contribute to the overall experience of consuming cannabis.

Plant Defense Mechanism: BVOCs, including terpenes, can serve as part of the plant’s defense mechanism against pests and pathogens. Some terpenes have antimicrobial and insect-repelling properties, helping the plant fend off potential threats.

Environmental Signaling: BVOCs can act as signaling molecules within the plant and between plants. They play a role in communication between different parts of the plant, as well as in interactions between plants. For example, certain BVOCs released by a stressed plant can signal nearby plants to activate their defense mechanisms.

Ecological Impact: BVOCs contribute to the overall ecological interactions in the environment. They can influence atmospheric chemistry, participate in the formation of aerosols, and even affect local weather patterns. The complex interactions involving BVOCs are part of the broader field of study in plant ecology.

Cultivation Practices: Cannabis cultivators may focus on optimizing the production of specific terpenes through various cultivation practices, such as selecting specific strains, adjusting environmental conditions, and using nutrient strategies. The goal is to enhance the desired aromatic and therapeutic qualities of the cannabis plants.

VOCS, BVOCS, and the need to control them:

- Human Health Concerns.

- Impact on Atmospheric Chemistry Models.

- Odor Control for Compliance and Abatement Plants.

- What are Those BVOCs Worth- Should we be Capturing them?

- How do we Properly Regulate and Enforce them?

Options for Controlling Odors:

Advanced Ventilation Systems:

- Invest in high-quality ventilation systems with HEPA/Merv13 filters to control and filter air within the cultivation facility.

- Use exhaust fans strategically to ensure proper pressures, air exchange and minimize the buildup of VOCs.

Carbon Filtration:

- Install activated carbon filters in ventilation systems to adsorb and neutralize odorous compounds, including BVOCs.

- Regularly maintain and replace carbon filters to ensure optimal performance.

Enclosed Cultivation Spaces:

- Consider enclosed cultivation spaces to better control air quality.

- Implement positive pressure systems to prevent air leakage and odors from escaping into neighboring areas.

Odor Neutralizers:

- Utilize odor-neutralizing agents or technologies designed to neutralize and eliminate unwanted odors.

- Test and choose products that are safe for both the environment and the cannabis plants.

HVAC Systems with Air Scrubbers:

- Install HVAC (Heating, Ventilation, and Air Conditioning) systems with air scrubbers, UVC, PCO or other tech to remove contaminants and odors from the air.

- Regularly service and maintain HVAC systems to ensure efficient operation.

Airtight Facility Design:

- Design cultivation facilities with airtight construction to minimize the escape of air and odors.

- Implement well-sealed doors, windows, and entry points.

Strategic Use of Exhaust Systems:

- Direct exhaust systems away from populated areas, ensuring that odors are dispersed effectively.

- Consider using odor control technologies in exhaust ducts.

Compliant Cultivation Practices:

- Follow local regulations and guidelines related to odor control and emissions.

- Keep up-to-date with changing regulations and adjust cultivation practices accordingly.

Community Engagement:

- Establish open communication with the local community to address concerns and demonstrate commitment to responsible cultivation practices.

- Consider implementing community-friendly initiatives, such as tours or informational sessions, to foster positive relationships.

Stages of filtration:

From outside to inside to back out… what’s the cycle and where can you impact? At what cost and with what level of effectiveness? Here are some guidelines:

- Assessment and Planning:

- Evaluate the specific VOCs and BVOCs emitted in the cannabis facility.

- Identify the sources and quantities of emissions.

- Determine the applicable regulations and standards.

- Develop a filtration strategy based on the assessment.

- Selection of Filtration Technologies:

- Choose appropriate filtration technologies tailored to the identified VOCs and BVOCs.

- Consider options such as activated carbon filters, biofilters, and other advanced filtration systems.

- Assess the compatibility of selected technologies with the scale and nature of the cannabis operation.

- Implementation and Installation:

- Install the chosen filtration systems in key areas of the facility where emissions occur.

- Ensure proper integration with existing ventilation and air handling systems.

- Conduct training for personnel on the operation and maintenance of the filtration equipment.

- Monitoring and Optimization:

- Implement continuous monitoring of VOC and BVOC levels to assess the effectiveness of filtration.

- Optimize filtration parameters based on real-time data and feedback.

- Regularly inspect and maintain filtration systems to maximize efficiency.

- Budget Considerations:

- Allocate funds for the initial assessment, including emissions testing and regulatory compliance analysis.

- Budget for the purchase, installation, and maintenance of filtration equipment.

- Consider long-term operational costs, including energy consumption and replacement of filter media.

Measurement of Success: Success in cannabis VOC and BVOC filtration can be measured through several key indicators:

- Emission Reduction: Measure the percentage of VOC and BVOC emissions effectively captured and reduced by the filtration system.

- Compliance: Ensure adherence to regulatory emission limits and standards.

- Air Quality Improvement: Monitor improvements in air quality within and around the facility.

- Product Quality: Assess the preservation of cannabis product quality, including aroma and flavor profiles.

- Operational Efficiency: Evaluate the efficiency and reliability of the filtration system in real-world conditions.

- Cost-effectiveness: Measure the overall cost-effectiveness of the filtration strategy, considering both initial investment and ongoing operational expenses.

Conclusion:

The need to control VOCs and BVOCs stems from concerns related to human health, atmospheric chemistry, compliance with regulations, industry reputation, and the preservation of product characteristics. The adoption of various technologies and best practices, such as advanced ventilation systems, carbon filtration, and compliant cultivation practices, offers cultivators a comprehensive toolkit to manage and mitigate the impact of these volatile compounds.

Additionally, understanding the distinct role of BVOCs in plant metabolism, defense mechanisms, environmental signaling, and ecological interactions emphasizes their importance in the broader context of cannabis cultivation. Terpene preservation becomes not only a regulatory requirement but also a means to enhance the economic value of the product and customer experience.

We have come a long way as cultivators, and regulators but ultimately, successful filtration strategies require a holistic approach that integrates technological solutions, compliance with regulations, community engagement, and continuous monitoring. By navigating through the stages of filtration and measuring success against key indicators, cannabis cultivators can strike a balance between industry growth and responsible, sustainable practices, ensuring a positive impact on both their business and the surrounding community.

Additional recourse:

Phase 1- Primary Air Cleaning

Placed within your room’s airflow, air from the environment containing microorganisms enters the purifier’s internal chamber. The reaction chamber creates non-thermal plasma and generates ROS. ROS is comprised of 5 short-lived, highly Reactive Oxygen Species:

- Atomic oxygen,

- Singlet oxygen,

- Hydroxyl radical,

- Superoxide and

- Peroxynitrite

These break down carbon-to-carbon bonds that sanitize the air and destroy all bacteria, molds, viruses, and other pathogens as they pass through the reaction chamber.

Phase 2- Secondary Surface & Air Cleaning

Provides Surface sanitation and continued Air sanitation. The purified air now diffused into the environment contains longer Reactive Oxygen Species:

- Gas-phased H2O2- hydrogen peroxide

- Low concentration levels of O3-ozone

That further sanitizes room air and surfaces. So again, in addition to treating the ambient air as it passes through the reaction chamber, using the H2O2 and O3 diffused into the environment, our units will further sanitize all Surfaces and control Odor, resulting in clean air and surfaces 24/7.

UVC:

Leave A Comment