Air flow crop steering is a cultivation technique used in indoor multi-tiered cannabis grow facilities to optimize plant growth and increase yields. It involves controlling the direction and speed of air flow within the grow space to manipulate the microclimate around the plants. And influence stomatal conductance that can drive phenotypic expression, biomass accumulation and overall plant vitality.

Growing cannabis indoors can be a profitable and efficient way to produce high-quality buds year-round. However, in order to maximize yields and profits, it’s important to optimize all 10 cardinal parameters that influence plant performance in every aspect of the growing environment, especially including air flow. By manipulating airflow you can influence the leaf temperature which will impact VPD, influence ambient conditions setpoints and utilize HVACD systems most efficiently. Airflow control will also allow the cultivator to push photosynthetic activity and get the most from every photon in the room. Furthermore, airflow has a dramatic impact on transpiration creating more opportunities to use media drybacks and influence generative expression.

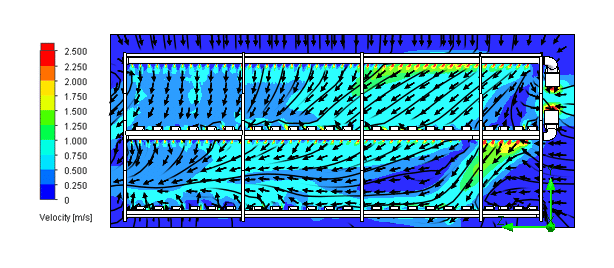

According to a white paper titled “Effects of air current speed on gas exchange in plant leaves and plant canopies,” * proper air circulation can greatly enhance plant growth and yields in a closed plant production module. The study investigated the effects of air velocities ranging from 0.1 to 0.8 m/s on photosynthesis in tomato seedling canopies under atmospheric CO2 concentrations. The results confirmed that controlling air movement is crucial for enhancing canopy photosynthesis under elevated CO2 levels as well as under normal CO2 levels in closed plant production modules.

This study has direct implications for the cultivation of cannabis in an indoor multi-tiered environment. By optimizing air flow and circulation, growers can achieve higher yields, increase revenue, and improve operational efficiency. Here are a few ways proper air flow can impact your cannabis cultivation operation:

- Higher Yields: Proper air flow helps ensure that your plants receive the right balance of carbon dioxide (CO2) and oxygen (O2), which are crucial for photosynthesis. Without enough CO2, your plants won’t be able to produce as much energy, leading to lower yields. Additionally, good air flow can help prevent heat stress, which can also reduce yields.

- Increased Revenue: Higher yields mean more product to sell, which can lead to increased revenue for your operation. By optimizing air flow and circulation, you can potentially produce more cannabis per square foot, maximizing your profits. The utilization of airflow can also influence phenotypic expression that is directly correlated to COAs/test results. Better COAs lead to higher Price per pound, better representation of each cultivar, better sell through numbers at the dispensary and ultimately a better customer experience. 40%THC and 5% terps doesn’t happen by accident, it’s because today’s cultivator uses science to allow the plant to express herself to her fullest extent

- Operational Efficiency: Proper air flow can also help improve the efficiency of your operation. By controlling air movement, you can better regulate temperature and humidity levels, which are key factors in plant growth. This can help reduce the risk of mold and disease, as well as cut down on the need for frequent watering and other maintenance tasks. Understanding airflow, convective cooling, and full air exchanges in the cultivation environment also allows today’s cultivator to get more performance from their HVACD system. This allows cultivators to reduce IPM application which inhibit productions of secondary metabolites and are an expensive labor cost.

In order to achieve optimal air flow in your indoor multi-tiered cannabis cultivation operation, there are a few key things to keep in mind:

- Achieve full air exchanges: Ensure that your grow space eliminates anaerobic conditions by providing conditioned, co2 rich air into the space, through the plants and out of the room. Proper air cycling allows for the plants to see consistent conditions and for the facility to have consistent results. This may include professional air balancing, monitoring filters to prevent CFM drops, and utilizing other equipment to effectively move air throughout the space.

- Monitor CO2 Levels: Use a CO2 meter to monitor the concentration of CO2 in your grow space to effectively maintain the appropriate PPM relative to stage of growth, PPFD, Temperature and other factors. This allows you to fine tune your SOPs to achieve the highest level of plant performance every minute of every day.

- Manage Temperature and Humidity: Understand your leaf temperature in order to effectively adjust your ambient conditions to maintain the appropriate VPD per stage of growth. This allows you to set predictable environmental itineraries per cultivar, avoid conditions that breed pathogens and reduce the labor and IPM needed to get to the finish line. Airflow will directly impact leaf temperature and is a powerful element that allows you to use VPD as a tool to achieve consistent success at scale.

By following these guidelines and optimizing air flow in your indoor multi-tiered cannabis cultivation operation, you can achieve higher yields, increased revenue, and improved operational efficiency. Don’t overlook the importance of proper air circulation when it comes to growing high-quality cannabis.

Our Air Glide is a best-in-class air flow solution that is purpose built for vertical cultivation. A product of cultivator-driven innovation, our system revolutionizes the industry standard to give growers an air circulation system that truly works for them and their cultivation needs. When you embrace airflow crop steering and invest in the right tools you might be blown away by the results.

Learn more about Air Glide here.

* Kitaya Y, Shibuya T, Yoshida M, Kiyota M. Effects of air velocity on photosynthesis of plant canopies under elevated CO2 levels in a plant culture system. Adv Space Res. 2004;34(7):1466-9. doi: 10.1016/j.asr.2003.08.031. PMID: 15825257. (https://pubmed.ncbi.nlm.nih.gov/15825257/)

Leave A Comment